Błąd formatu e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Aktualności

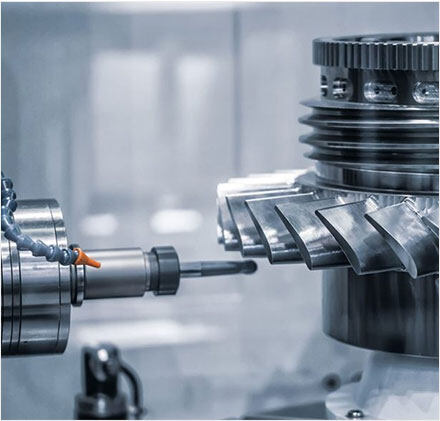

7 Amazing Applications of Customized CNC Processing(1)

Several industries, including large and small companies such as workshops and repair shops, have adopted customized CNC processing because it can create customized parts related to specific applications.

Computer numerical control (CNC) machining is a manufacturing process involving the use of computers to control many complex machine parts. It is widely used because it can deal with almost all materials - metal, plastic, and so on.

The unique advantages of customized CNC processing, such as accuracy, turnaround time, and quality, are ideal in all industries from the medical industry to carpentry to leisure.

How does custom CNC work in the following applications?

Customized CNC processing has become the basic requirement of almost all industries, whether complex or traditional production methods. Its accuracy and accuracy are particularly necessary for companies that may affect human life in the event of component failure, such as:

-

Oil and gas industry

Because the oil and gas industry needs long-term operation and high-quality machine parts that can be well combined, the components used need to be accurate, durable, and high-strength; Without these factors, accidents, leaks, and inefficient production are inevitable.

This fact requires the use of customized CNC machining to manufacture oil and gas parts that require greater tolerance, reliability, and complex details, such as pins, rods, pistons, cylinders, valves, and drill bits.

For example, CNC can help prevent operating errors of drilling rigs found in remote areas. It ensures that the components used on the drilling rig are qualified, all-weather, and can maintain function for a long time to avoid the need for continuous replacement and maintenance.

In addition to ensuring zero operational errors, CNC processing can also meet the needs of large quantities in oil and natural gas production. Due to the ability to process components in large quantities, these machines cover the complexity of manufacturing petrochemical parts.

-

Military and defense industry

Defense and military departments also rely on flexible and reliable technology to manufacture parts that can withstand the worst terrain. Because they must comply with strict government production measures, the military and national defense industries have invested heavily in modern numerical control processing solutions.

Military applications involve aviation, communications, transportation, medical, electronics, marine, and other industries. This means that these departments need to meet the needs of the defense sector by using the latest technology to manufacture components such as electronics, aircraft components, transportation, and communication components.

Custom CNC processing helps to produce large parts such as alloys and durable metals and helps to quickly upgrade functions to achieve first-class safety.

-

Medical industry

The accuracy, speed, and material versatility of CNC processing in the production of customized and medical safety components make it an almost critical manufacturing process in the medical industry. Machining parts such as disposable surgical tools, bedside monitoring equipment, implants, MRI machines, orthopedic equipment, and many other medical devices require very strict tolerances. CNC processing has the technical resources for precision production and manufacturing of biosafety and biocompatible medical components.

Customized CNC processing workshops are also conducive to the rapid production of customized medical parts. Manufacturing meets the certification standards and minimizes errors that hurt human life, such as misdiagnosis and failure.

Searching for a cnc mechanical processing, cnc metal processing, cnc manufacturing service manufacturer from China, you can get high-quality products at a nice price.